Automated Wire Harness Testing for Aerospace, Defence & Military Systems

Ensuring Zero-Failure Reliability: The Critical Role of Wire Harness Testing for Defence Systems

In the defence and aerospace sectors, there is no room for “good enough.” Whether it is an unmanned aerial vehicle (UAV), a naval imaging system, or a ground-based tactical network, the integrity of every wire and connection is mission-critical. A single faulty harness can lead to more than just system downtime—it can compromise operational safety and mission success.

A recent feature in ASSEMBLY Magazine titled “Testing Wire Harnesses for Defense Systems” highlights how top-tier US defence contractors, such as PVP Advanced EO (AEO), located in Tustin CA (mentioned in the original article here), are tackling these challenges by moving away from manual testing towards sophisticated, automated solutions.

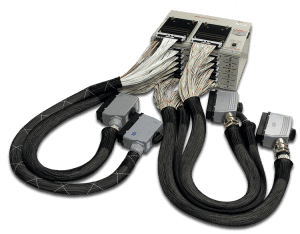

The Complexity of Modern Defence Harnesses

Modern defence electronics are undergoing a shift towards unprecedented density and miniaturisation. As the ASSEMBLY article illustrates, the sheer volume of connection points within advanced electro-optical and infrared sensors makes traditional manual continuity checks practically obsolete. What was once a manageable task has become a significant bottleneck that is both labour-intensive and highly susceptible to human error.

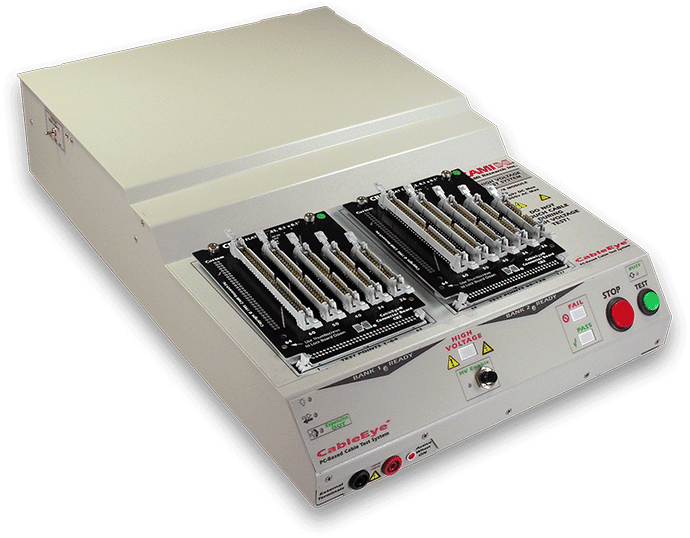

The industry is responding to this challenge by integrating sophisticated automated testing platforms into the heart of the production floor. These systems are designed to:

-

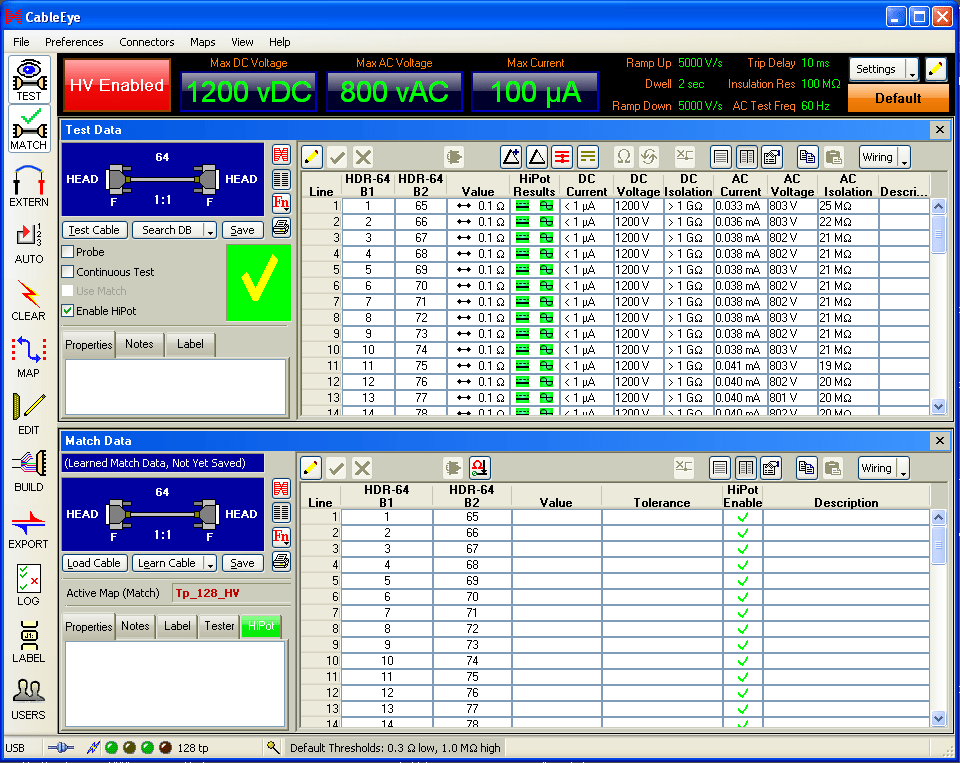

Instantly Identify Complex Faults: Rather than checking one pin at a time, automated testers scan thousands of points in seconds, pinpointing opens, shorts, and miswires with digital precision.

-

Measure Precision Resistance: By employing 4-wire Kelvin measurements, these systems can detect minute variations in resistance. This is essential for ensuring that solder joints and crimps meet stringent milliohm-level specifications—defects that a standard multimeter would simply overlook.

-

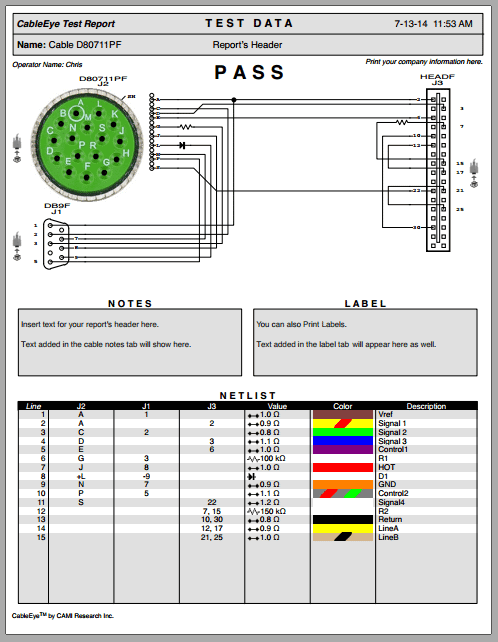

Establish Full Traceability: In a sector governed by strict compliance, every test result matters. Modern systems generate comprehensive, wire-by-wire reports that can be linked via barcode to specific serial numbers. This creates a permanent digital “birth certificate” for every assembly, providing the transparent audit trail required by prime contractors and MoD auditors alike.

Moving Beyond Simple Continuity: The Standard for High-Reliability

A fundamental takeaway from the ASSEMBLY feature is that basic “pass/fail” continuity testing is no longer sufficient for modern mission-critical hardware. While a simple beep might confirm a connection exists, industry standards such as MIL-STD-202, AS9100, or IPC-620 demonstrate that it fails to reveal the quality or longevity of that connection under duress.

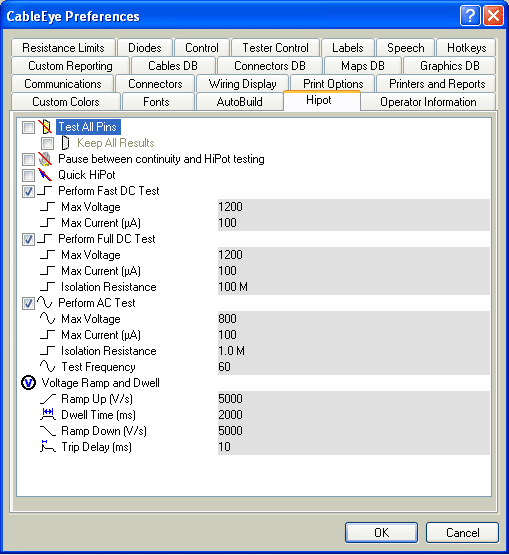

For ruggedised defence applications, testing must delve deeper into the electrical integrity of the assembly. Measuring dielectric breakdown and insulation resistance (often referred to as Hipot testing) is vital for identifying potential failures that only manifest when a system is under load. Furthermore, the checking capacitance of twisted pairs ensures that signal integrity remains uncompromised—a crucial factor for the high-speed data transfer required by modern imaging and communication systems. These rigorous checks guarantee that wire harnesses can survive the extreme vibrations, vacuum conditions, and thermal stresses typical of military and aerospace environments.

Defence and aerospace manufacturing is about low-volume high-mix production. To manage this technical complexity across high-mix content, without sacrificing throughput, many manufacturers are now adopting “learning” modes. By using a known-good “golden” harness, the testing system can automatically detect and store the correct wiring map, resistance values, and specifications. This transition from manual programming to automated detection significantly reduces setup times and eliminates the risk of human error during the configuration phase. The result is a more agile production line and a robust quality control process that provides the precision required for defence-grade certification.

Cimbian: Your Partner in Defence-Grade Testing

At Cimbian, we recognise that the standards set for the defence industry are the benchmark for all high-reliability manufacturing. Our range of

From prototyping and assembly to post-deployment diagnostics, we provide the tools necessary to ensure your wiring harnesses are “mission-ready.” Much like the systems discussed in the ASSEMBLY feature, our solutions prioritise automation, precision, and ease of use, allowing you to eliminate the testing bottleneck without sacrificing quality.

Download our defence capability brochure

Read the original full article on ASSEMBLY Magazine:

Ready to Reduce Increase Efficiency?

By partnering with Cimbian UK, you are investing not just in a tester, but in a complete quality control ecosystem backed by decades of expertise. We offer the precision and speed necessary to meet today’s demanding manufacturing standards.

Don’t allow outdated techniques damage your reputation.

Cimbian: Excellence in Cable & Harness Testing

Based in the UK, Cimbian specialises in delivering precision-engineered testing and manufacturing systems for mission-critical applications, such as wire harness testing for defence systems. We understand that in the defence sector, “failure” is not an option. By providing state-of-the-art automated testing solutions, we help UK manufacturers improve throughput, eliminate human error, and achieve full traceability for complex harness assemblies. Discover our full range of solutions at

If you found this page interesting please share it with your friends and colleagues.