Ensuring Cable Safety with Insulation Withstand Testing: Why Precision Matters

When it comes to cable assemblies, safety and reliability are non-negotiable. One of the most critical tests performed to ensure these qualities is the Insulation Withstand Test, also known as Dielectric Breakdown Testing, high-voltage withstand testing, or Isolation Testing. This high-voltage test verifies that the insulation within a cable assembly can withstand a specified voltage without allowing excessive current to flow, confirming that the product is safe for use in the field… or is it?

What is an Insulation Withstand Voltage Test?

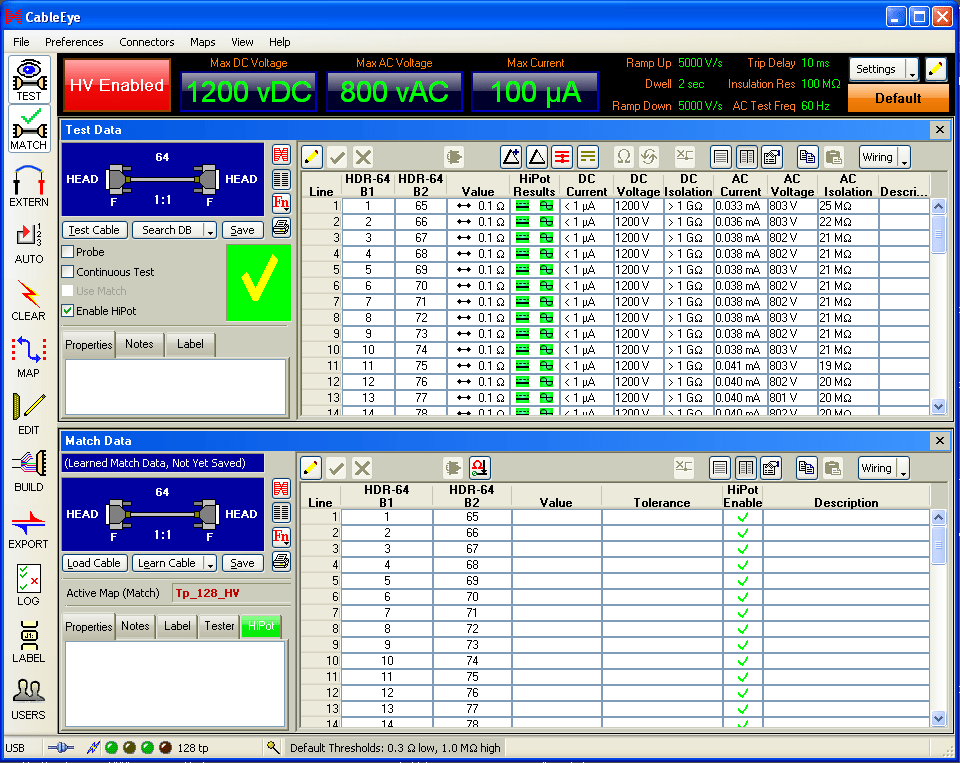

Typically conducted during end-of-line testing, this process involves applying a known high voltage and monitoring the resulting current. If the current remains below a preset threshold, the assembly passes the test; however, not all test systems are created equal—and that’s where the CableEye® HVX Series stands out.

Going Beyond the Basics with CableEye®

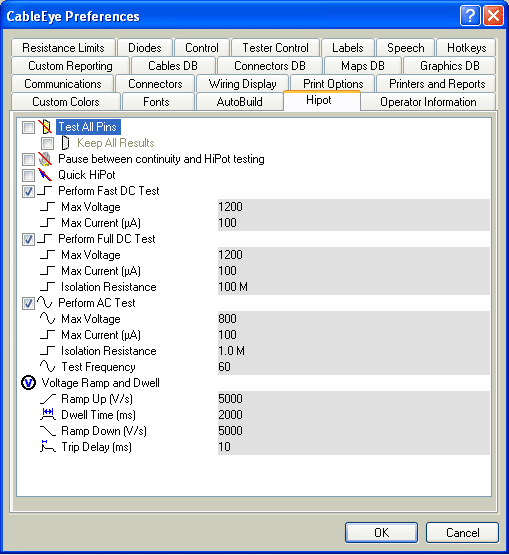

While many HiPot testers can perform a basic insulation withstand test, the CableEye HVX Series offers advanced features that ensure a more accurate, repeatable, and reliable result. For instance, when high voltage is applied to a cable, the inherent capacitance can cause the power supply to trip prematurely. To counter this, CableEye allows users to precisely program both the voltage ramp-up and ramp-down rates in 1V increments. This fine control enables the system to accommodate the charging characteristics of the cable under test, ensuring the full test voltage is applied without triggering a fault.

Intelligent Current Monitoring

Another key advantage of the CableEye system is its programmable current range, from 0.05mA to 1.5mA. This ensures that the assembly is protected throughout the test, including during ramp-up and ramp-down phases. The system continuously monitors current levels, preventing damage while maintaining test integrity.

Additionally, CableEye allows for a programmable trip current—a brief allowance for over-current conditions caused by voltage ringing when the maximum test voltage is reached. This feature ensures that minor, short-lived current spikes don’t result in a failed test or reduced voltage application.

Confidence in Every Test

Once the maximum voltage is applied and stabilised, the system enters a programmable dwell time, during which the high voltage is maintained before ramping down. This ensures the insulation is tested under sustained stress, providing a more thorough validation.

All of these programmable parameters—ramp rates, current limits, trip thresholds, and dwell times—combine to deliver a test that is not only precise but also repeatable and trustworthy. With CableEye, manufacturers can ship their cable assemblies with full confidence that the test specifications were met—not compromised.

More than just HiPot

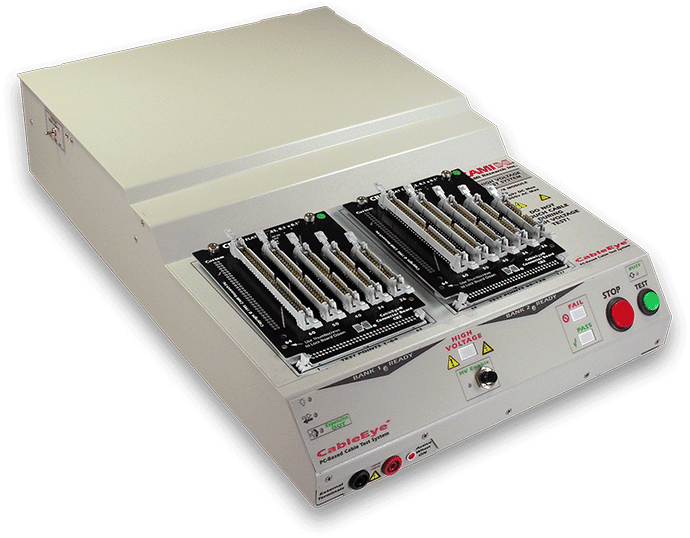

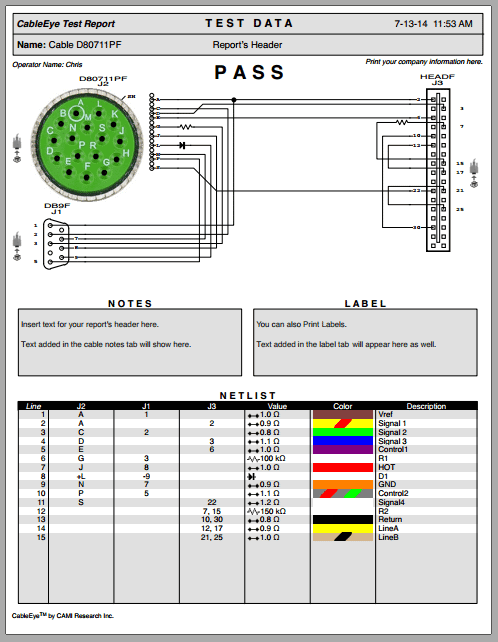

The CableEye® HVX series of testers are based upon the well-established low voltage M3Z and M4 CableEye® testers from CAMI Research. What this means is that all products are tested for the low-voltage parameters including Continuity, Resistance, Diodes. Only after the assembly under test passes these tests will the CableEye® HVX system enter HiPot test mode.

A single test station for a one-stop test solution.

A well-considered investment

By investing in precision tools for insulation withstand testing, companies signal a clear commitment to excellence. It’s not merely about passing a test; it’s about protecting your brand, your clients, and ultimately, the end-users who depend on your products every day. In this context, precision isn’t just important—it’s indispensable.

Not All Cable Testers Are the Same

In a world where product safety and compliance are paramount, having the right tools makes all the difference. The CableEye® HVX Series doesn’t just perform insulation withstand testing—it elevates it, ensuring your assemblies meet the highest standards of quality, safety, and reliability.

Related Content

If you found this page interesting please share it with your friends and colleagues.